Hydrogen-specific rectifier transformer

- Details

I. Product Description Converter technology encompasses three operating modes: rectification, inversion, and frequency conversion,

with rectification being the most widely used. Most industrial rectified DC power supplies are generated from the AC power grid through

rectifier transformers and rectifiers. The electrochemical industry is the largest user of rectifier transformers, used for electrolyzing

non-ferrous metal compounds to produce aluminum, magnesium, copper, and other metals; electrolyzing salt to produce chlor-alkali;

and electrolyzing water to produce hydrogen and oxygen. The depletion of fossil fuels, environmental degradation, and frequent

extreme weather events have spurred the explosive growth of the hydrogen energy industry. Hydrogen energy is an abundant, green,

and low-carbon secondary energy source, gradually becoming one of the important carriers of global energy transition. Under the

requirements of carbon peaking and carbon neutrality, the production of high-purity hydrogen and oxygen through renewable energy

sources such as photovoltaic, wind, or hydropower, combined with hydrogen production rectifier equipment and water electrolysis

technology, will have wider applications in the global economy.

II. Performance Characteristics

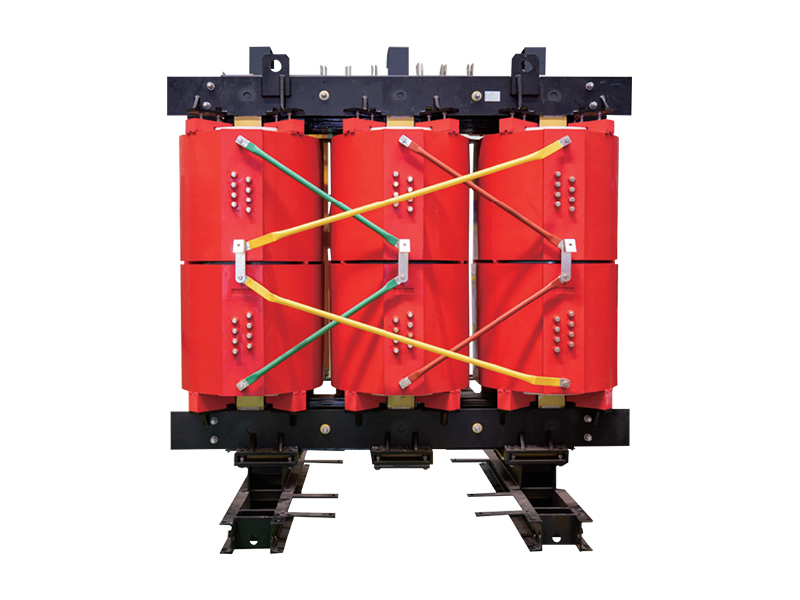

1. Safe and Reliable. The transformer is made of non-toxic, flame-retardant epoxy resin, resulting in high mechanical strength,

flame retardancy, fire resistance, and no pollution.

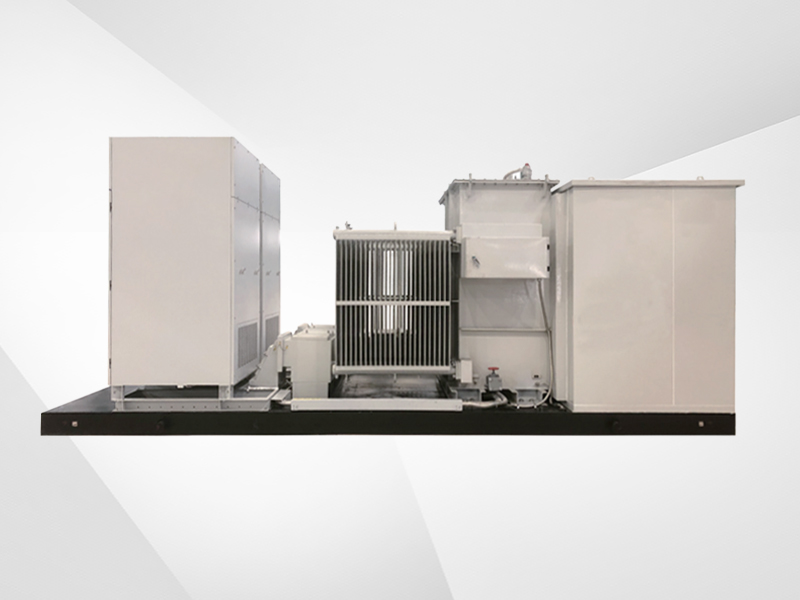

2. Convenient Installation. The dry-type rectifier transformer is delivered as a complete unit and can be put into operation

immediately upon installation, offering convenience and efficiency.

3. High Overload Capacity. Maximum overload capacity reaches 200%.

4. Low Noise. Noise level is 3-5 dB lower than the national standard.

5. Cost-Effective. The dry-type rectifier transformer can be installed together with rectifiers and other electrical equipment, eliminating

the need for a separate distribution room, saving space and reducing initial investment.

6. Customized Design. Flexible design and rapid response can be provided according to specific customer requirements.