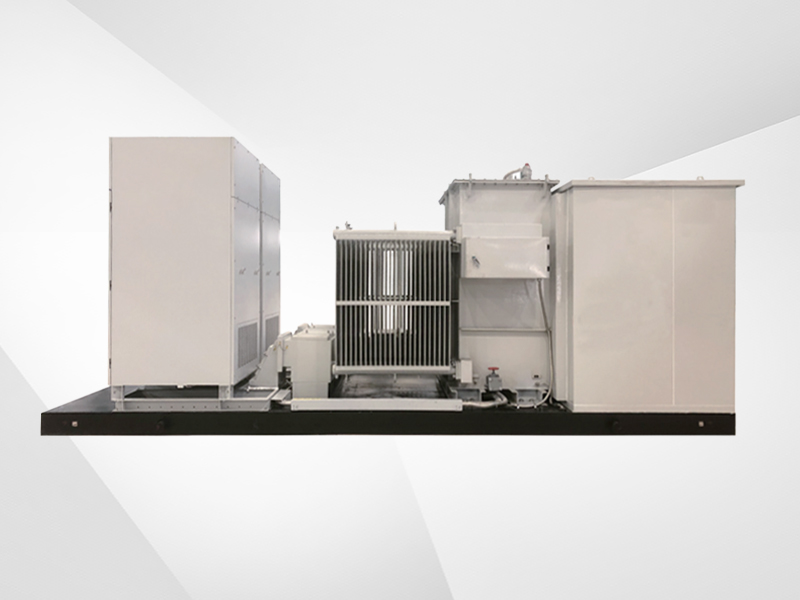

New Energy Oil-immersed transformer for energy storage

- Details

I. Structural Advantages

1. The core structure has been changed from the traditional oblong core to a near-elliptical core structure,

improving the transformer's resistance to sudden short circuits.

2. High-density laminated wood is used as clamping components. By changing the copper cable routing method,

the internal tank width is significantly reduced, making the overall structure more compact. This also helps suppress

stray losses caused by leakage magnetic fields.

3. The internal transformer positioning and switch installation method have been changed. The high-voltage riser

has been modified to a manhole-less structure, reducing the risk of oil leakage.

II. Quality Control Advantages

1. From a product quality perspective, the testing methods of GB/T 7354 are strictly followed. Partial discharge tests

are performed on each new energy transformer to ensure that the partial discharge level is ≤50pC at 1.2Ur and

≤100pC at 1.4Ur (Ur is the transformer's rated voltage). 2. For products of the same model and batch, 10% (≥1 unit)

of the total number of units are randomly selected for lightning impulse testing and temperature rise testing to further

ensure the electrical insulation and mechanical performance of the products.

3. Based on the magnitude and frequency of the harmonic current injected into the transformer provided by the user,

the losses of harmonic current are fully considered to avoid exceeding the temperature rise limits of the transformer

oil top layer and windings. The capacity increase requirements caused by harmonic currents are also considered to

ensure the service life of the transformer.

4. According to the user's requirements and combined with the on-site operating environment, the transformer anti-corrosion

treatment is strictly carried out in accordance with the requirements of ISO 12944.