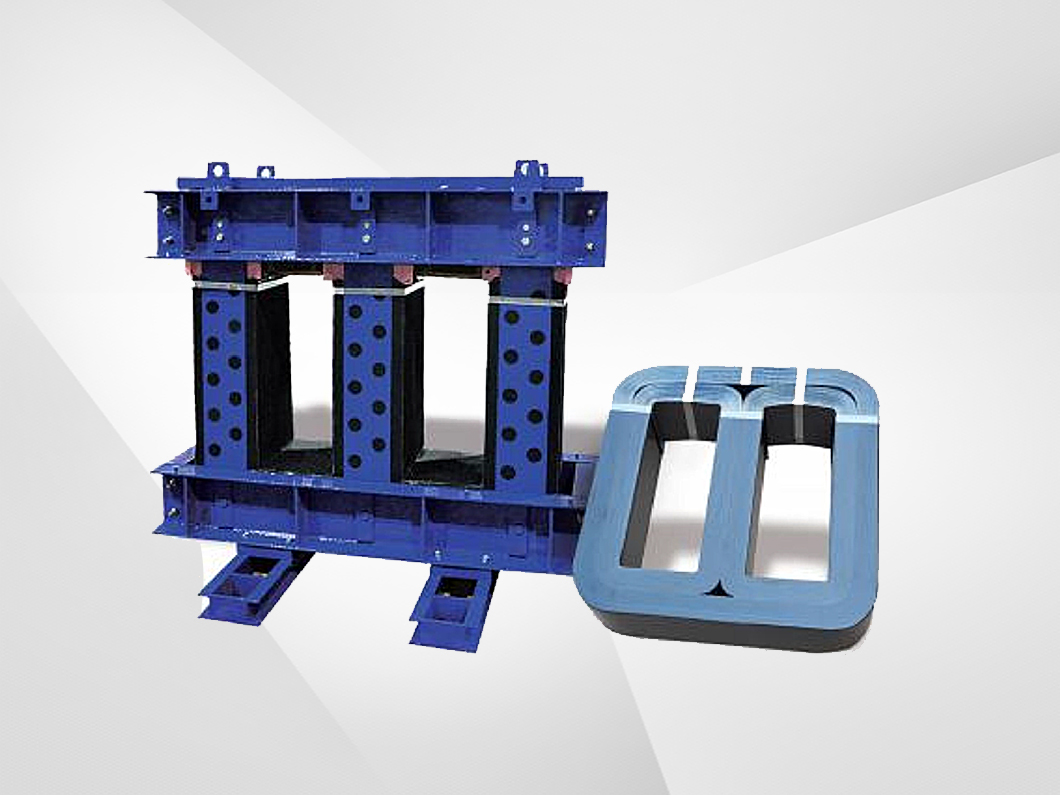

Dry-type Transformer Amorphous Alloy Core Round Core

If you are interested in our products or need technical supports and service,please contact us as bellowing:

- Details

Outline:The iron-based amorphous alloy is composed of 80%fe and 20%siand b,the alloy of the metal element is rapidly solidified.Anamorphous material formed by the art,having an extremely highquality,superior physical and electrical.

Technical Characteristics:1. High saturation magnetic induction intensity--reduce the number of winding turns,reduce thevolume of the product

2. High resistivity,low coercivity--improve product efficiency

3. Low loss(equivalent to 1/3-1/5 of silicon steel sheet)--reduce the temperature rise of the productand improve the efficiency

4. Low excitation power--reduce the no-load current of the product,reduce the copper loss of theprimary winding

5. Variable magnetic conductivity--different heat treatment processes of iron core can be used tomeet different application requirements.

6. Good temperature stability--can work at 130℃ for a long time

| Performance index | Iron-based amorphous alloy(Giantway) | Other Manufacturers |

| Saturation Flux Density(T) | 1.6 | 1.59 |

| Coercive Force(A/m) | ≤3.8 | ≤4 |

| Maximun Permeability(μ) | >20×104 | >20×104 |

| Iron Loss 50hz 1.35t(W/kg) | <0.14 | <0.16 |

| Exciting Power 50hz 1.35t(VA/kg) | <0.16 | <0.18 |

| Lamination Factor | ≥0.88 | ≥0.86 |

| Magnetostrictive Coefficient | 27×10-6 | 27×10-6 |

| Resistivity(μΩ ·cm) | 114 | 130 |

| Density(g/cm3) | 7.25 | 7.18 |

| Crystallization Temperature(℃) | 478 | 550 |

| Curie Temperature(℃) | 394 | 415 |

| Strength Of Extension(MPa) | 1500~2000 | 1500~2000 |

| Vickers Hardness(HV) | 980 | 980 |

| Thickness(μm) | 24-26 | ≤30 |