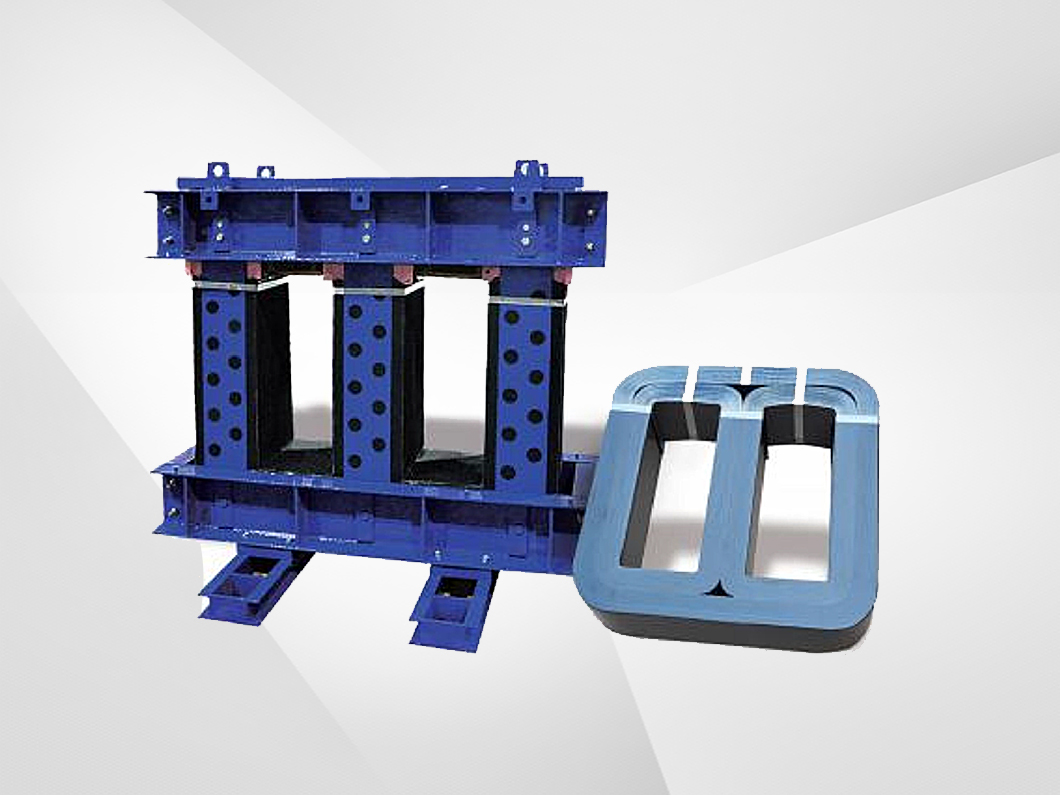

3-D Amorphous Core

- Details

Amorphous is used in various shapes to build oilimmersed and dry type transformers.

Transformers with 3-D amorphous cores are:

a.Cruciform cross section of core(nearly round)

b.Cost competitive

c.Easier and faster to build core transformers

d.Have lesser No Load Loss and magnetizing currents

e.Very lowinrush currents and better no load power factor

f.Very low harmonics

g.Consume lesser noise compared to normal core

h.Because the coil cross-section is round,it greatly improves the transformer's ability tosudden short circuits.

i.All transformers can be easily atmuch lesser cost compared to normal core.

Manufacture processes of 3-D amorphous core

To make 3-D amorphous core transformer,amorphous ribbon is slited into 6 or 7 widths from mother amorphous ribbon depending on the transformer design.

a. Using special curve slitting machine,the single ribbon would be slit into two long trapezoidal pieces and wound onto a drum.

b. Taper slit ribbon rolls are loaded onto decoiler of 3-D amorphous core winding machine,it could winding the core with round shape.

c. After winding a round core,it will use a special pressing machine for making the round shape to a rectangle shape.Three core loops are required to assemble a three phase transformer core.

d. The whole processes of slitting and winding.One person is required to operate the machine,only need input parameters and observe.

e. After 3 core complete core loops are pressed,the three cores loop are picked using a crane and load them onto a simple assembly table.

f. The three limbs(phases)are tied together using 3M strap.Bottom core frame with insulation are fixed and the core assembly is turned to facilitate coil assembly and assembly of top yokes,using silicone on the surface of the core for curing purposes.

g. In case annealing is required(we strongly recommend it to reduce no load loss and current),the whole core loop are assembled together,annealed in a batch amorphous annealing furnace and used.

h. Coil winding can be done using the special coil winding machines.Core coil assembly is very easy and fast.Available workmen can easily be trained in a very short time.