Maintenance-free Dehydrating Breather For Transformer

- Details

The maintenance-free dehydrating breathers of the Premium series feature a built-in heating element, which enables sensor-controlled dehydrating. This eliminates visual inspections that are required regularly and minimizes costs. dehydrating breather is available with an alpha or beta control system.

· Maintenance-free dehydrating breather

· Use of glass cylinders for optimizing the regeneration process and for excellent weather resistance

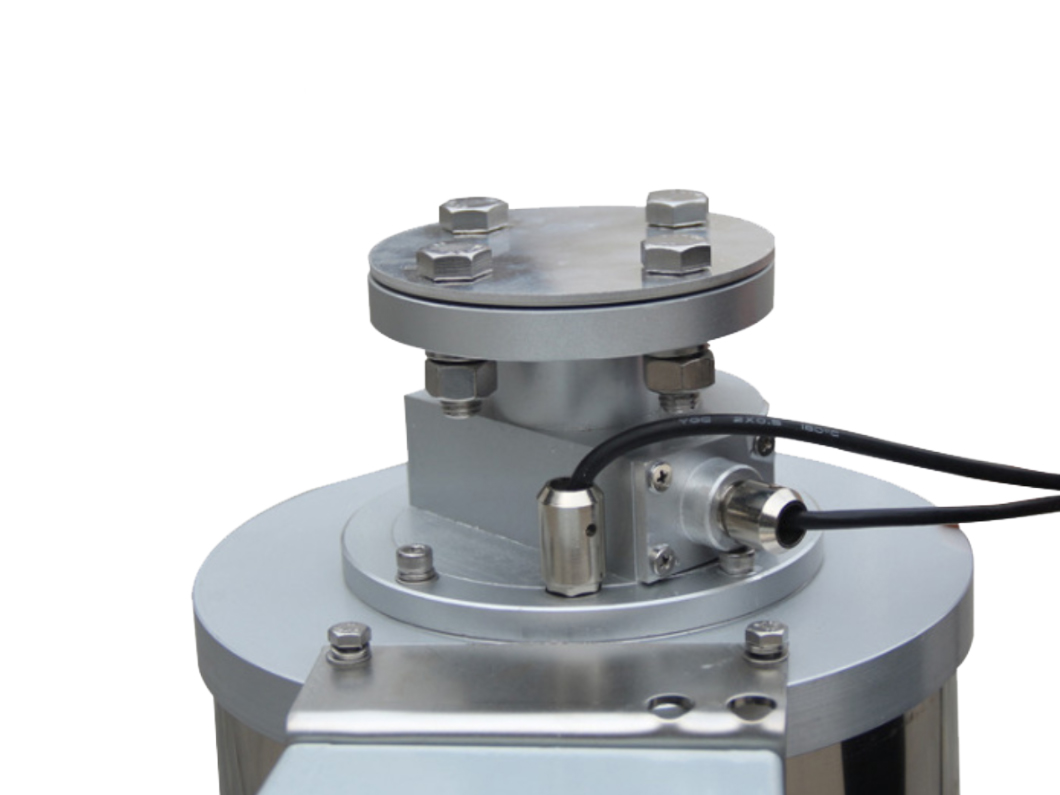

· DIN flange for optimal mounting

· Test button for performing self-tests

· Optional: Offshore model, filter heater for use in temperatures as low as -50 °C and a data logger

· Optional: Protection of the electrical lines from damage (such as gnawing by animals)

The dehydrating breather is used to dry the intake air of transformers.

If the operating temperature of the transformer drops, air will be sucked in through the oil container, cleaned of dirt particles and subsequently dried by the silica gel inside the assembly

The oil trap prevents any permanent contact between the silica gel and the moist ambient air and also filters the inflowing air. If the temperature rises, air is expelled from the conservator and flows through the transformer dehydrating breather type L in the opposite direction. The size of the dehydrating breather which has to be used depends on the oil volume and the frequency of the air exchange.

Desiccant Air Breather is mainly used on the tank with moisture absorption and air filtration. Firstly,the moisture in the incoming air is absorbed when passing through the drying agent. After passing through the drying agent, the dirt particles are caught in the air filter element; these can reduce the pressure loss caused by the fluctuation of oil and the changing of temperature. With the moisture absorbed and the dirt particles caught, the reliability and the processing ability in the hydraulic system will be decreased and the life of the oil and the machine will be extended.

AS moisture is absorbed, the drying agent granules will gradually change color from blue to pink. The granules should be changed when the color changes to pink.

It is just need to open the cover when changing the drying granules. The granules can be put in the 150ºC oven for drying until it turns blue again.

Note: the broken drying granules can not be used again.

Product characteristics:

When moisture is absorbed, the drying agent granules will gradually change color from blue to pink.The granules should be changed when the color changes to pink.

2.1 Top cover material

High strength carbon steel

2.2 Straight tube material

PVC

2.3 Filter element material

Cotton wood pulp

2.4 Type of connection

Inch threaded connection

Code | Type | ΦD | H | Silicagel weight | For Transformer Oil | Transformer capacity |

YC.688.6 | MX1-3 | 225 | 518 | 3 | 10000 | ≤10000Kva |

YC.668.7 | MX1-5 | 225 | 710 | 5 | 22000 | ≤50000Kva |

YC.668.8 | MX1-10 | 225 | 710 | 10 | 35000 | ≤500000Kva |